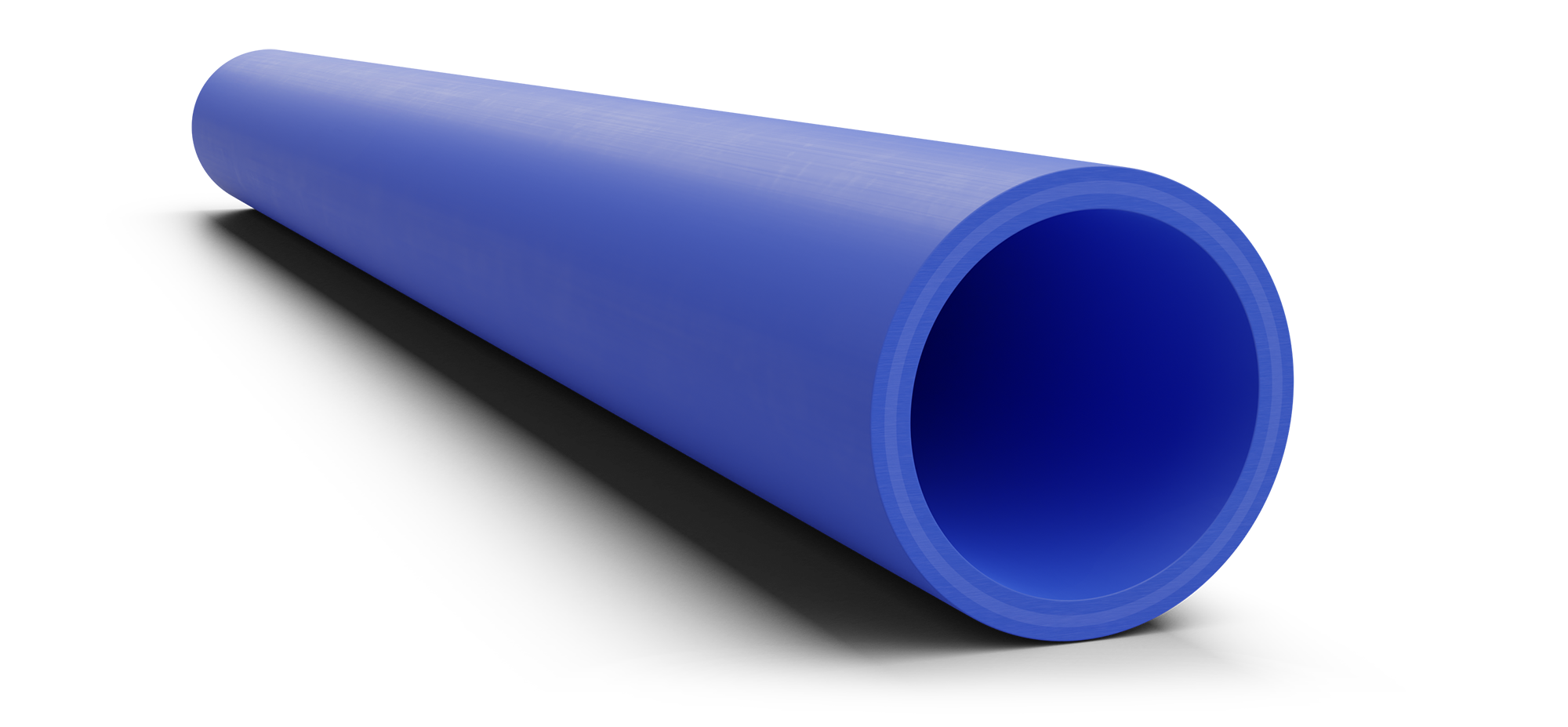

Aquatherm Blue®

A smarter alternative to traditional steel piping.

Aquatherm Blue delivers the performance expected in mission-critical systems while eliminating the corrosion, leak risk, labor intensity, and long-term inefficiencies associated with steel.

Benefits

- Corrosion-free PP-RCT construction with 50+ year service life

- Heat-fused joints eliminate leak-prone mechanical connections

- Lightweight design reduces installation time by up to 75%

- Smooth interior surfaces optimize flow and reduce energy costs

- No chemical treatment or cathodic protection required

Applications

- Chilled and condenser water systems

- Potable water distribution

- Geothermal and ground-source heat pumps

- Process cooling applications

With fusion-welded connections, lightweight installation, and zero corrosion, Aquatherm Blue delivers decades of reliable performance in demanding mechanical systems.

Aquatherm Blue Pipe® vs. Steel Piping

(PP-RCT)

Lower overall cost due to faster installation, reduced labor, and no welding certifications required

Higher total cost from welding, threading, certifications, and longer installation time

Completely corrosion-free PP-RCT material requires no chemical treatment or cathodic protection

Requires ongoing corrosion monitoring, chemical treatment, and eventual replacement

Heat-fused joints create homogeneous connections stronger than the pipe itself

Threaded and welded joints are potential leak points that degrade over time

Fusion connections virtually eliminate leak potential throughout system life

Mechanical joints and corrosion create ongoing leak risks

3-4x faster installation with simple heat fusion tools and no hot work permits

Slow installation requiring certified welders, hot work permits, and fire watch

No open flames, no toxic fumes, lightweight handling reduces injury risk

Welding hazards, heavy lifting injuries, and respiratory risks from fumes

Smaller crews with basic training can complete installations efficiently

Requires certified welders and larger crews for heavy material handling

Virtually maintenance-free with no scaling, corrosion, or joint degradation

Ongoing maintenance for corrosion control, joint repairs, and eventual replacement

50+ year expected service life with consistent performance

15-25 year typical life before corrosion requires replacement

Smooth interior surface maintains optimal flow and reduces pumping energy

Interior roughness and scale buildup increase friction and energy costs

Lower thermal conductivity and smooth surfaces reduce energy consumption

High thermal conductivity and rough surfaces increase operational costs

Consistent lead times and fast installation keep projects on schedule

Supply chain variability and slow installation create schedule risks

1/8 the weight of steel simplifies handling and reduces structural load

Heavy material requires special equipment and structural considerations