Services / Fabrication

Preventing problems before they reach the field

Fabrication issues discovered during installation are expensive to correct. PipeX moves complexity off the jobsite and into a controlled shop environment where every joint, dimension, and connection can be verified before delivery.

When spools arrive ready to install, field crews can focus on assembly rather than problem-solving.

Estimation

PipeX estimates fabrication cost and schedule impact. We support rapid quoting with a clear understanding of scope, material needs, and production timelines.

Scan-to-Fab

Point cloud or 3D scan-to-fabrication modeling translates field conditions into accurate spool drawings. Existing conditions inform routing, clearances, and coordination details.

BIM support

BIM coordination reviews confirm constructability and detect conflicts before fabrication begins. PipeX works with project models to verify clearances and fit.

Fabrication drawings

Production-ready shop-ready fabrication drawings define every connection, dimension, hanger location, and coordination requirement.

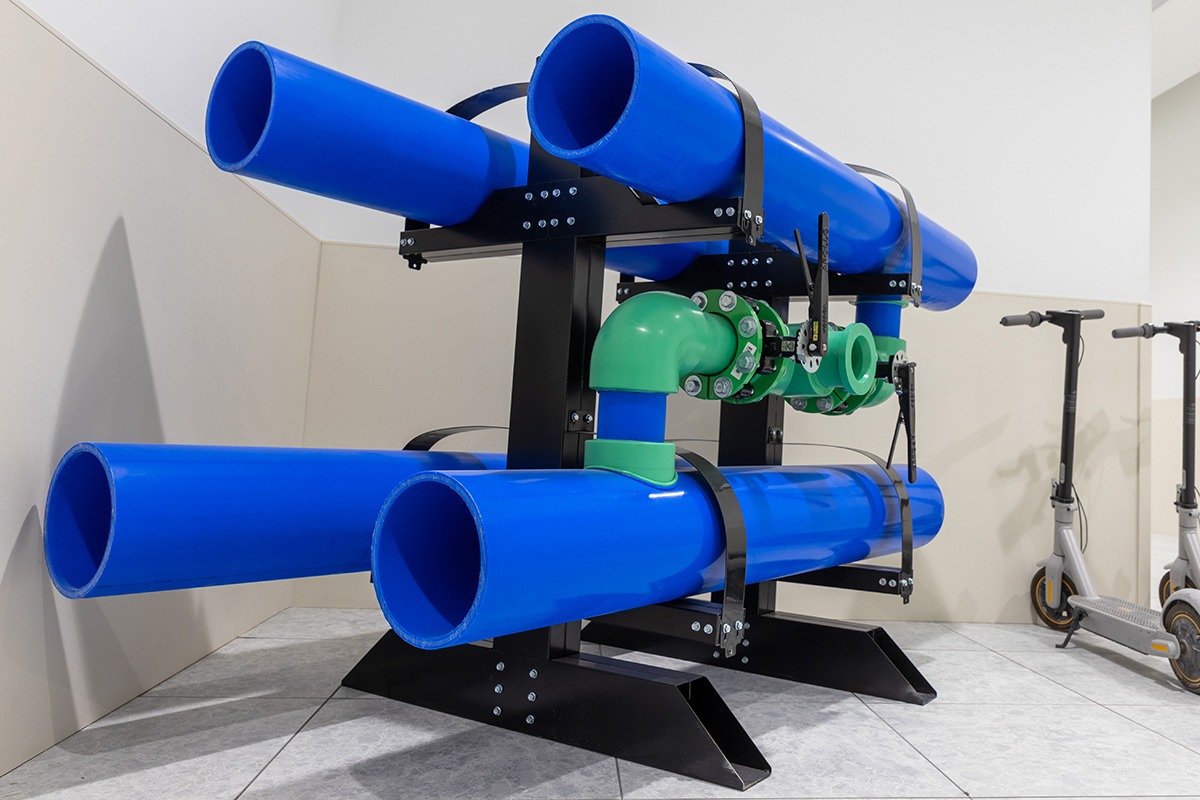

Fabrication

PipeX completes prefabricated PP-RCT spool assemblies ready for installation. Controlled shop conditions ensure consistent quality, proper fusion, and fast turnaround.